Onsite Deployable Decontamination Room

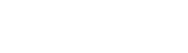

The Personnel Decontamination System (PDS) is an airlift-ready turnkey transition room system designed for attachment to a controlled maintenance hangar space where hazardous materials (HMs) are present. Built out of two standard ISO containers, it contains an air and wet shower, an industrial sink, washer/dryer for PPE, and lockers for street clothing. It enables continuous, safe maintenance within both austere FOBs and permanent facilities.

PRODUCT DESCRIPTION

Product Features

- PDS includes an air and wet shower, an industrial sink, a washer and dryer for PPE, and lockers for personal effects.

- PDS is contained entirely within two shipping containers.

- Air liftable

Technical Specifications

| Description | Capabilities/Value |

| Dimensions | Contained in two 20’x8’x8’6” ISO containers. |

| Power Requirements | PDS requires 141.5kW for whole system. |

Product Benefits

- Give workers easy access to decontamination

- Quick two-day installation

- Easy to deploy

The PDS system was installed at Cannon AFB during the remodeling of the onsite decontamination suite.

PDS was designed with the health of aircraft maintainers in mind. Many bases have inadequate HM disposal systems, leading to dangerous contamination around bases and within workers’ homes, often causing long-term health effects (including cancer) depending on the chemicals being worked with. The system is designed for a quick two-day install with a three-person team, and the flexibility of the ISO container layout makes PDS an easy-to-deploy solution to protect the health of the warfighter and support teams.

CONNECT WITH US

Interested in talking to us about this product?

Please contact us, our aim is to serve you and your ideas.