SoluStat™ – Advanced Stripping Solution Control

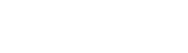

Solustat is an innovative control system for characterizing metal finishing solutions by measuring, interpreting, and correcting bath solution performance drivers.

Normal degradation of stripping bath performance leaves production crippled. Slow and inconsistent strip rates, unscheduled line shutdowns, substrate corrosion investigations, and part condemnation can be avoided with Solustat. It provides non-expert users real-time bath performance feedback and can actively control the stripping rate.

PRODUCT DESCRIPTION

Product Features

- Solustat is capable of monitoring and controlling multiple types of bath solution.

- Solustat can quickly measure and monitor solution tanks.

- Solustat can predict chemical bath service life.

Technical Specifications

| Description | Capabilities/Value |

| Compatible Solutions | MetalX B9, Nitric Acid, CRP-065, Crest Silver Strip |

| Measurements Taken | Substrate Corrosion Rate, Coating Strip Rate, pH, and Temperature |

| Testing Time | 45 min |

| Power Requirements | 120 VAC 20A |

Product Benefits

- Save money on testing.

- Reduced man hours automating testing.

- Provide analytical data to track bath and schedule maintenance.

- Extend bath service life.

- Reduced chance of damaging parts.

- Predict Bath life.

- Prevent substrate corrosion attack

Current technologies require a high degree of skill to operate and cannot provide onboard data interpretation or generate human or machine instructions for bath correction. Solustat brings laboratory analytics to the production line and bridge the longstanding gap between human interpretation and machine automation.

CONNECT WITH US

How can we help you?

Here at the Figure Engineering our aim is to serve you and your ideas.